Logic Diagram PLC: Understanding PLC Ladder Logic and Programming Basics

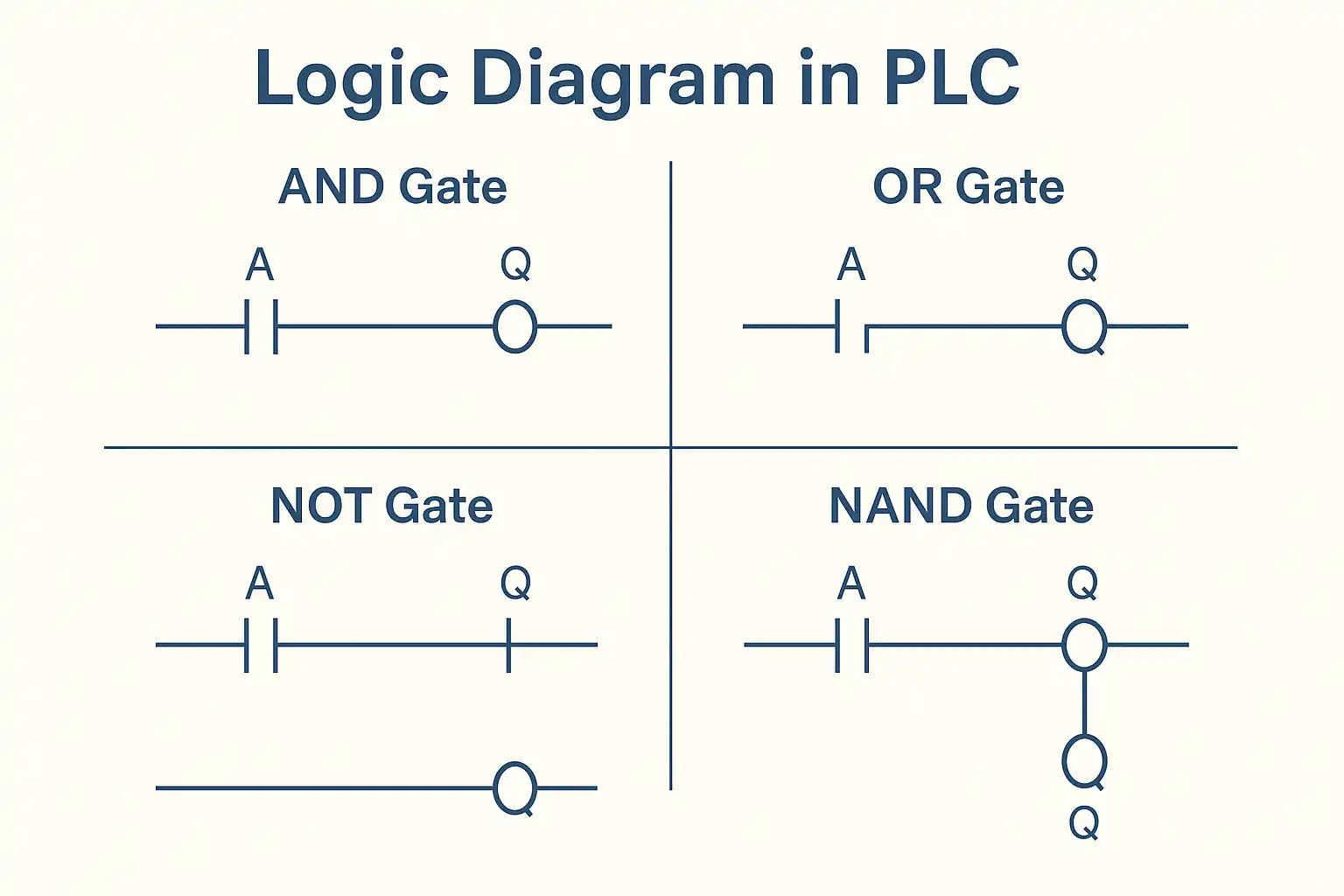

In industrial automation, Programmable Logic Controllers (PLCs) play a crucial role in controlling machinery, managing systems, and improving productivity. One of the most widely used programming methods for PLCs is the ladder logic diagram, a visual tool that represents how the logic flows through the control system. This blog will guide you through the essentials of the logic diagram PLC, introduce you to PLC ladder programming, and help you understand how logical gates like AND and NAND are implemented using ladder logic. A logic diagram PLC is a schematic representation of the control logic that a PLC executes. These diagrams are essential for designing and understanding the behavior of automated systems. The most common form is the ladder logic diagram, which resembles a ladder with vertical rails and horizontal rungs—each rung representing a logical operation. Ladder logic (also called ladder programming) is the traditional programming language for PLCs. It mimics the look and structure of electrical relay logic diagrams used before digital PLCs became standard. In PLC ladder programming, the logic is built with contact symbols (representing inputs or conditions) and coil symbols (representing outputs or actions). These elements are organized into PLC ladder diagrams that run from left to right. PLC programming ladder logic is preferred for several reasons: Let’s look at a basic PLC ladder diagram that turns ON a motor when two input conditions (Start and Safety Switch) are true. |----[ Start ]----[ Safety ]----( Motor )----| This is equivalent to an AND Gate Ladder Diagram where the motor turns on only when both conditions are true. Understanding ladder diagram for logic gates is key to mastering PLC logic. Let’s break down a few examples: Logic: Output is ON only if Input A and Input B are both ON. |----[ A ]----[ B ]----( Q )----| Logic: Output is ON if either Input A or Input B is ON. |----[ A ]-----------( Q )----| |----[ B ]--------------------| Logic: Output is ON when Input A is OFF. |----[/A ]------------( Q )----| Logic: Output is OFF only if both A and B are ON; otherwise, it’s ON. |----[ A ]----[ B ]----[/]----( Q )----| Let’s say we want to design a control system where: Ladder PLC Program: |----[ Sensor ]----[/ E-Stop ]----( Conveyor )----| This real-world scenario uses ladder logic programming to ensure safety and operational control. These basic symbols form the backbone of any basic PLC diagram. PLC ladder logic is commonly used in: It’s an essential tool for automation engineers and electricians alike. A logic diagram shows the theoretical flow of logic operations, while a ladder diagram shows how those logic operations are implemented in a PLC using ladder symbols. It visually represents the logic program in a format that mimics electrical relay control systems, making it easy to design and debug automation systems. Use two normally open contacts in series to represent an AND condition. Yes. Its visual format is especially intuitive for those familiar with electrical wiring and logic circuits. Yes. PLCs also support Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC), but ladder logic remains the most common. Mastering the logic diagram PLC and becoming comfortable with PLC ladder logic is crucial for anyone involved in automation or industrial control systems. Whether you're designing a simple ON/OFF control or a complex logic circuit involving AND, OR, and NAND gates, ladder logic gives you the tools to make it happen—visually, efficiently, and reliably. Start with basic PLC ladder diagrams, explore real-world use cases, and you’ll quickly realize how powerful and versatile ladder logic programming really is.What Is a Logic Diagram in PLC?

What Is Ladder Logic?

Key Components of Ladder Logic:

Why Use PLC Programming Ladder Logic?

Basic PLC Ladder Diagram Example

PLC Diagram for Logic Gates

✅ AND Gate Ladder Diagram

✅ OR Gate Ladder Diagram

✅ NOT Gate Ladder Diagram

✅ NAND Gate Ladder Diagram

Ladder Logic Programming: Real-World Application

Basic PLC Diagram Symbols

Where Is Ladder Logic Used?

FAQs on PLC Ladder Logic and Diagrams

Q1: What is the difference between a logic diagram and a ladder diagram?

Q2: What is the function of a PLC ladder diagram?

Q3: How do I create an AND gate in ladder programming?

Q4: Is ladder logic easy to learn?

Q5: Can PLCs use languages other than ladder logic?

Conclusion

Related Blogs