PLC Applications, How PLC Power Modern Industry

Programmable Logic Controllers (PLCs) have become the backbone of automation across multiple industries. From simple machine control to complex plant operations, the role of a PLC is unmatched. If you’re curious about PLC applications, this guide will walk you through real-world use cases, key features, and its growing importance in areas like mechatronics and industrial automation. Understanding the features of PLC helps in grasping why they are used across so many applications. Here are the major highlights: These features make PLCs a go-to solution for engineers and industries that demand precise, efficient, and safe control systems. PLC uses span across various sectors. From manufacturing to infrastructure, here are some common plc applications: 1. Manufacturing Automation These are just a few examples. The application of plc in industry is virtually limitless and continues to expand with advancements in technology. Mechatronics blends mechanics, electronics, and computing—making PLCs a natural fit. So, what are the applications of PLC in mechatronics? Here are a few specific use cases: PLCs in mechatronics are crucial for real-time control, safety, and integration with sensors and actuators. Their ability to interface with both mechanical and electronic components makes them ideal for intelligent machine systems. Let’s take a simple PLC application example from a bottling plant: The bottling line needs to: A PLC is programmed to: This PLC-controlled system ensures high-speed operation with accuracy and consistency—without manual intervention. Modern PLC products are evolving with technological advancements. New trends include: These trends are transforming how industries monitor, control, and optimize their systems. PLC is used in conveyor systems, robotic arms, machinery control, packaging lines, and process industries like chemicals, textiles, and food. In mechatronics, PLCs control motors, sensors, actuators, and intelligent machines—making systems smarter and more autonomous. Because PLCs are flexible, easier to program, occupy less space, are more reliable, and can be easily modified without rewiring. Yes, while not common in typical residential setups, PLCs are used in high-end or industrial home automation systems for lighting, HVAC, and energy management. Yes. A single high-capacity PLC can manage several machines or even an entire plant, depending on the I/O and processing power. The PLC concept has revolutionized automation across industries. From basic control tasks to complex intelligent systems, PLC applications are everywhere—from packaging plants to smart mechatronic systems. Understanding the plc uses, recognizing the application of plc in industry, and learning what are the applications of plc in mechatronics opens doors for engineers, technicians, and businesses aiming to optimize processes and enhance productivity. Whether you’re a student, a plant manager, or an automation professional, diving deep into PLCs is a smart move in today’s tech-driven industrial world.Key Features of PLC

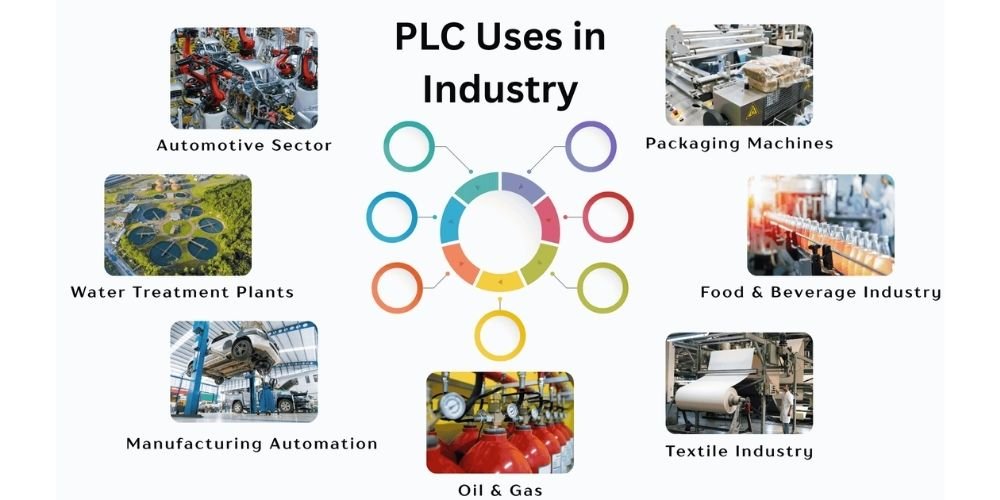

Common PLC Uses in Industry

2. Packaging Machines

3. Food & Beverage Industry

4. Automotive Sector

5. Textile Industry

6. Water Treatment Plants

7. Oil & Gas

What Are the Applications of PLC in Mechatronics?

Application of PLC in Industry: Case Study Example

Problem:

Solution:

Emerging Trends in PLC Applications

FAQs About PLC Applications

Q1: What are the main applications of PLC in automation?

Q2: How is PLC used in mechatronics?

Q3: Why is PLC preferred over traditional relay systems?

Q4: Are PLCs used in home automation?

Q5: Can one PLC control multiple machines?

Conclusion

Related Blogs