What a Micro Size PLC Can Handle: Small Controller, Big Capabilities

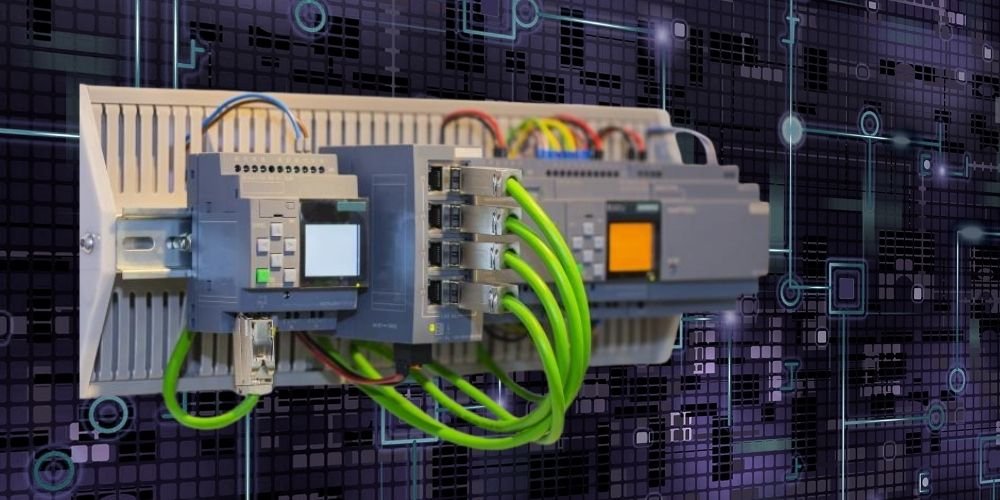

In today’s rapidly evolving automation world, space-saving and cost-effective solutions are more important than ever—especially for small-scale applications. This is where a micro PLC steps in. But the question many ask is: What can a micro size PLC handle? This article explores the capabilities of micro PLCs, the type of applications they’re ideal for, and how they compare to larger PLC systems. A micro PLC, also called a small or compact programmable logic controller, is a low-cost, space-saving automation device designed for handling basic control tasks. It comes with a built-in CPU, power supply, and a limited number of I/O points—all in a single compact unit. Micro PLCs are ideal for: Despite their size, the micro size PLC can handle a surprising range of control tasks. While micro PLCs are not intended for large-scale plant automation, their capabilities are more powerful than many assume. Here's what a typical micro size PLC can handle: Micro PLCs can manage basic ON/OFF control of digital devices such as: Many micro PLCs come with 8–40 digital inputs and outputs, perfect for small machines or panels. Some micro PLCs support analog inputs/outputs for controlling: This makes them useful in applications where basic analog control is needed, such as small HVAC systems or simple dosing pumps. Micro PLCs can handle: This functionality is ideal for simple automation sequences that require precise timing without needing a full-sized PLC. Modern micro PLCs often come with built-in communication ports such as: This allows them to communicate with HMIs, VFDs, SCADA systems, or even cloud-based platforms. Some examples of what a micro size PLC can handle in real-world scenarios include: These tasks may seem simple, but require precision and repeatability—something micro PLCs deliver efficiently. So while traditional PLCs dominate in complex industrial systems, the micro size PLC can handle most basic automation needs at a fraction of the cost and space. Choosing a micro PLC for small applications comes with multiple benefits: This makes them ideal for startups, small machine builders, and cost-conscious projects. While a micro size PLC can handle many tasks, it’s important to know their limitations: Some leading brands provide reliable micro PLC models, including: These micro PLCs are widely available and supported by easy-to-use programming software. The short answer to what a micro size PLC can handle is: a lot more than you think. From simple digital control to small-scale analog processing and communication, micro PLCs offer a practical solution for countless automation tasks. Whether you're automating a small machine, upgrading a manual process, or experimenting with an IoT prototype, a micro PLC delivers reliable performance, flexibility, and affordability—without overcomplicating your system. Micro PLCs can handle digital and analog I/O control, timers, counters, basic machine automation, and communication with other devices. Yes, many micro PLCs are rugged and designed for light industrial applications. However, they are best suited for non-critical or small-scale tasks. Micro PLCs have limited I/O and functionality but are more compact and cost-effective. Full-sized PLCs are modular and better for complex systems. Yes, many micro PLCs support HMI integration via Modbus or serial/Ethernet communication. Micro PLCs are used in packaging, agriculture, HVAC, education, building automation, and small machinery control.What Is a Micro PLC?

What Micro Size PLC Can Handle: Key Capabilities

1. Digital I/O Control

2. Analog I/O Processing (in Advanced Models)

3. Timer and Counter Operations

4. Communication with Other Devices

5. Small-Scale Machine Automation

Micro PLC vs Traditional PLC: What’s the Difference?

Feature Micro PLC Traditional PLC Size Very compact Larger, modular units I/O Capacity 64+ I/O points (expandable) Cost Low Medium to high Application Scope Simple and standalone systems Complex, multi-process systems Expansion Highly expandable Advantages of Using a Micro PLC

Limitations of Micro Size PLCs

Restricted Communication: Advanced protocols may be unavailable

No Redundancy: Not designed for mission-critical systems requiring failover

Limited Memory and Processing: Not ideal for data-heavy applications or complex logicCommon Brands That Offer Micro PLCs

Conclusion: Micro PLCs—Small Size, Smart Control

FAQs About Micro PLCs

Q1: What can a micro size PLC handle?

Q2: Are micro PLCs reliable for industrial use?

Q3: What is the main difference between a micro PLC and a full-sized PLC?

Q4: Can I use a micro PLC with an HMI?

Q5: Which industries use micro PLCs?

Related Blogs