AB PLC, The Power Behind Industrial Automation

When it comes to reliable and scalable industrial automation, few names stand as tall as AB PLC. Short for Allen Bradley PLC, this brand has become synonymous with high-performance control systems used across various industries—from manufacturing and packaging to energy and water treatment. In this guide, we'll explore what makes AB PLCs so popular, the hardware options available, and how Allen Bradley PLC software simplifies automation programming. An AB PLC refers to a Programmable Logic Controller (PLC) manufactured by Allen-Bradley, a brand owned by Rockwell Automation. These controllers are industrial-grade computers designed to control machines, processes, and factory automation systems. Allen Bradley PLCs are known for their: Whether it's a simple conveyor belt or an entire manufacturing line, an AB PLC can handle it. Allen-Bradley offers a variety of PLC families to suit different automation needs: 1. Micro800 Series Each series of Allen-Bradley PLCs supports Ethernet/IP communication, remote diagnostics, and modular expansion options. One of the strongest advantages of using an AB PLC is the power and usability of Allen Bradley PLC software. These programming tools are designed for ease of use, robust logic development, and integration with Rockwell’s entire automation ecosystem. With Allen Bradley PLC software, programming becomes faster, smarter, and more consistent—ideal for reducing downtime and boosting productivity. Here’s what sets AB PLCs apart in the world of automation: Choosing an Allen Bradley PLC is a long-term investment in reliable, future-proof automation. AB PLCs are trusted across a wide range of industries, including: Their wide acceptance and support make them the go-to choice for system integrators, plant engineers, and OEMs alike. If you’re new to Allen Bradley PLCs, here are a few steps to begin: From rugged hardware to intuitive programming tools, AB PLCs are engineered for excellence. Whether you’re automating a basic process or managing a large-scale plant, Allen Bradley PLCs deliver unmatched performance, reliability, and flexibility. And with Allen Bradley PLC software like Studio 5000, building and managing automation logic becomes smoother and smarter—making your journey into industrial control easier than ever. AB PLC refers to Allen Bradley Programmable Logic Controller, a product line from Rockwell Automation. RSLogix 500, RSLogix 5000, and Studio 5000 are the main Allen Bradley PLC software platforms. Yes, the Micro800 series is ideal for small standalone control systems. Industries like automotive, packaging, oil & gas, water treatment, and food processing commonly use AB PLCs. They are premium products with high durability and performance, making them cost-effective for long-term use.What Is an AB PLC?

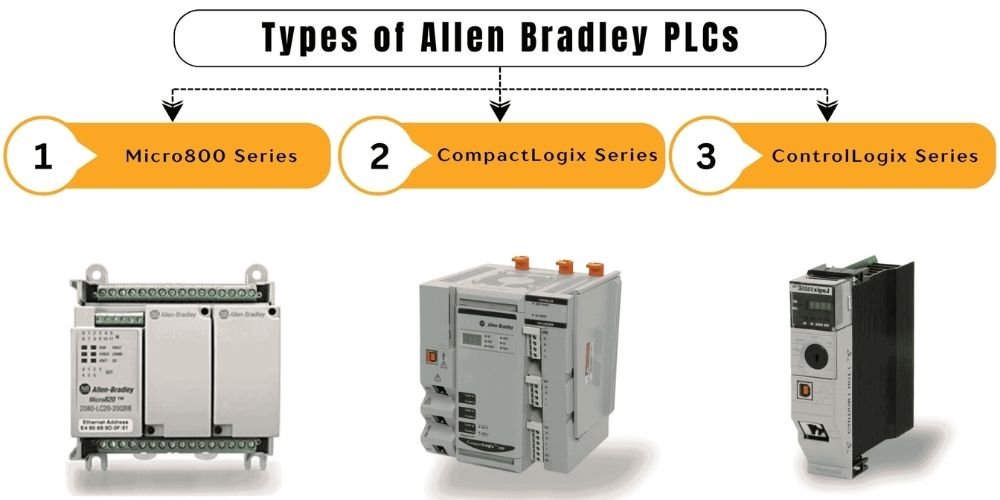

Types of Allen Bradley PLCs

2. CompactLogix Series

3. ControlLogix Series

Allen Bradley PLC Software: RSLogix & Studio 5000

RSLogix 500 / RSLogix 5000

Studio 5000

Why Choose an AB PLC Over Others?

Feature AB PLC Advantage Scalability From small machines to plant-wide control Integration Seamless connection with Rockwell systems Reliability Built to handle harsh industrial conditions Support & Resources Global support, training, and documentation Ecosystem Works with FactoryTalk, PanelView, and more Industries That Use AB PLCs

Getting Started with AB PLC

For training, Rockwell Automation offers tutorials, certification courses, and free project libraries that help you learn faster.Conclusion: AB PLC—A Leader in Automation

FAQs About AB PLC and Allen Bradley Systems

Q1: What does AB PLC stand for?

Q2: What software is used to program Allen Bradley PLCs?

Q3: Is AB PLC suitable for small applications?

Q4: Which industries use Allen Bradley PLCs?

Q5: Are AB PLCs expensive?

Related Blogs