Understanding Different Types of PLCs for Industrial Success

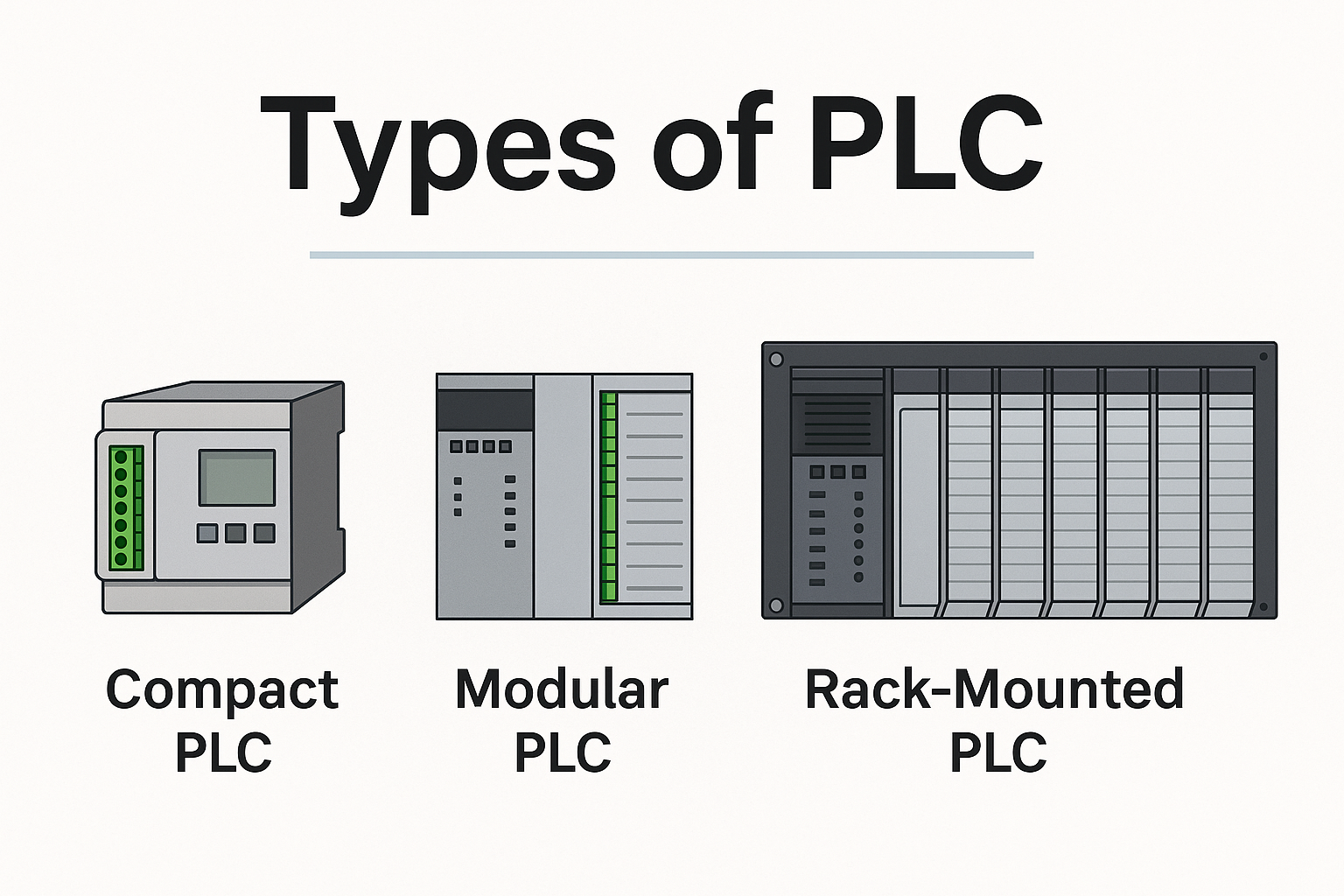

As automation engineers, we know the Programmable Logic Controller (PLC) is the heart of every industrial system. But asking "Which PLC should I use?" is like asking "Which car should I drive?"—the answer depends entirely on the application. Choosing the wrong PLC type can lead to unnecessary complexity, limited future scalability, or a cost overrun on a tight budget. Our goal at Anadi Automation is to ensure your production is robust, scalable, and optimized from day one. Here is a practical breakdown of the different PLC architectures and when we use them in the field. The Compact PLC, sometimes called the "Brick" PLC, is the simplest and most cost-effective option. The CPU, power supply, and a fixed number of Input/Output (I/O) points are housed in a single, non-modular unit. While some models offer limited expansion modules (often 2–4 modules), the core functionality remains fixed. The Modular PLC is the standard for almost all large-scale, mission-critical industrial processes. This type uses a chassis or rack where the components are separate, interchangeable modules: Rack/Chassis: Provides the physical structure and the backplane (the high-speed internal bus). CPU Module: The processor itself. Power Supply Module: Powers the backplane and all other modules. I/O Modules: Slots for digital, analog, and specialty cards (like motion control). While not a PLC itself, Distributed I/O is a critical modern architecture that works in conjunction with Modular PLCs. I/O modules are removed from the main PLC cabinet and placed closer to the field devices (sensors, valves, motors) on the factory floor. They communicate back to the main Modular PLC (the controller) via a high-speed industrial network like PROFINET or EtherNet/IP. When designing an automation solution, we use a simple checklist to match the application to the PLC architecture: Understanding these architectures is the difference between a system that works and a system that excels. At Anadi Automation, our expertise spans across all major PLC manufacturers, including Siemens, Allen-Bradley (Rockwell), Mitsubishi, and Schneider Electric. This vendor-neutral knowledge allows us to recommend the precise PLC type—whether it's a Compact MicroLogix or a fully redundant Siemens S7-400H—that offers the best performance and ROI for your unique industrial challenge. We don't just sell components; we engineer lasting solutions. Kiran Kothmire is a Senior Automation Specialist at Anadi Automation with over 15 years of hands-on experience designing, commissioning, and optimizing industrial control systems. Answer: The primary difference is scalability. A Compact PLC is an all-in-one unit with a fixed number of I/O points, making it cost-effective for small, static applications. A Modular PLC uses a rack/chassis system, allowing you to add, replace, and upgrade I/O cards and the CPU as your system grows, offering superior flexibility and high-availability options. Answer: They work together. The Modular PLC is the main controller that executes the core logic. Distributed I/O is simply a set of remote modules placed closer to field devices (sensors, motors) on the factory floor. They use industrial Ethernet to communicate with the main PLC, reducing long wiring runs and installation costs in large facilities. Answer: The Modular PLC is almost always the required choice for high-speed, high-precision control applications like servo motor systems. This is because it offers dedicated motion control modules and a high-speed backplane that ensures the ultra-fast data transfer and low scan times needed for synchronized, multi-axis motion. Answer: Generally, no. All major PLC types support the primary programming languages defined by the IEC 61131-3 standard (Ladder Logic, Function Block Diagram, Structured Text, etc.). However, advanced features specific to Modular PLCs (like Safety or Motion Control) may require specialized instruction sets or function blocks within the programming software.From Compact to Modular: Choosing the Right PLC Architecture

By Kiran Kothmire, Senior Automation Specialist, Anadi Automation

1. The Compact (Fixed) PLC: The Workhorse for Small Systems

Architecture

Practical Applications (When to Choose)

Pros Cons Low Initial Cost and minimal panel space. Limited Scalability for future needs. Simple Installation with no need for a backplane/chassis. Fixed I/O Types: Cannot easily mix and match specialty I/O cards. Faster Scan Time due to the integrated design. Lack of Redundancy options for critical systems. 2. The Modular PLC: Power and Scalability for Complex Operations

Architecture

Practical Applications (When to Choose)

3. The Distributed I/O System (Rackless/Remote)

Architecture

Practical Applications (When to Choose)

Reducing Wiring Costs: It replaces hundreds of copper wires with a single, high-bandwidth Ethernet cable.

Harsh Environments: The remote I/O blocks can be IP-rated (e.g., IP67) and designed to withstand dust, moisture, and high temperatures better than standard cabinet I/O.Making the Right Choice: An Engineer’s Checklist

Factor Low I/O / Simple (Choose Compact) High I/O / Complex (Choose Modular/Distributed) I/O Count Less than 64 Digital/Analog points. Greater than 128 points, or requires specialty I/O (e.g., vision, high-speed counters). Response Time Cycle time in the tens of milliseconds is acceptable. Requires sub-millisecond scan time (e.g., motion control, high-speed press). Future Growth Zero anticipated expansion or changes. System is expected to scale by 20% or more in the next 5 years. Physical Space All field devices are located within 20 meters of the central cabinet. Devices are spread over a large factory floor (requires Distributed I/O). System Uptime Failure is an inconvenience (e.g., can wait 30 minutes for a restart). Failure is catastrophic (e.g., requires dual-CPU redundancy and high-speed diagnostics). Partner with Our Multi-Brand Experts

About the Author:

FAQ

Q1. What is the main difference between a Compact and a Modular PLC?

Q2. How is a Distributed I/O system different from a Modular PLC?

Q3. Which PLC type is best for high-speed servo motor control?

Q4. Does the PLC type affect the programming language I use?

Related Blogs