Top Advantages of PLC. Why PLCs Are the Backbone of Industrial Automation?

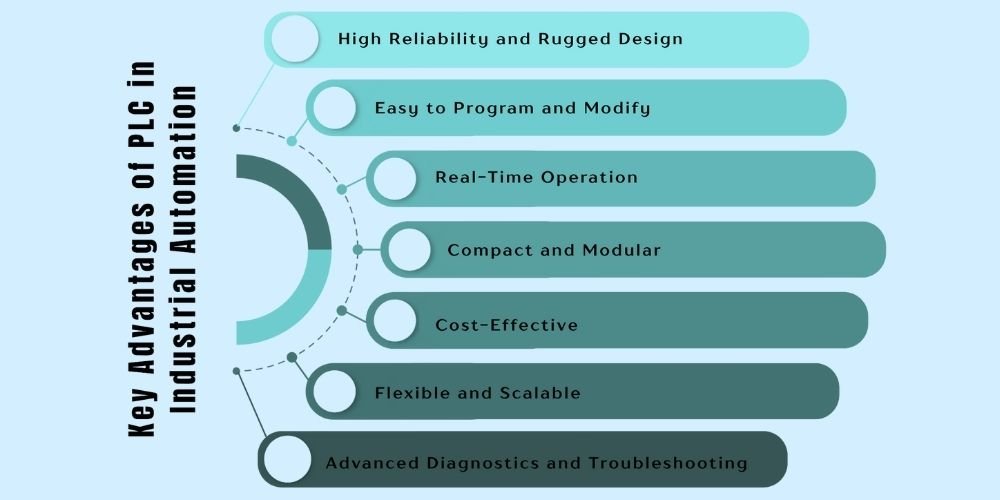

In the fast-evolving world of industrial automation, Programmable Logic Controllers (PLCs) play a critical role in ensuring efficient, reliable, and flexible control systems. But what exactly are the advantages of PLC? Why are they so widely used, and how do they compare to traditional control methods? This blog explores the benefits of PLC, discusses the disadvantages of PLC, and explains why PLC is preferred over traditional logic systems in most industries today. Let’s break down the main plc advantages and disadvantages, starting with why PLCs are the top choice for control systems. 1. High Reliability and Rugged Design PLCs are built to withstand harsh industrial environments—including vibration, dust, temperature extremes, and electrical noise. This makes them highly dependable and long-lasting. Thanks to user-friendly programming languages like Ladder Logic, even technicians with minimal programming background can configure and update a PLC’s logic with ease. PLCs operate in real-time, processing data from sensors and adjusting outputs in milliseconds. This ensures precise control over time-critical processes. Modern PLCs come in space-saving designs and offer modular expandability. You can add or replace modules without redesigning the entire system. Compared to complex and costly traditional relay-based control systems, PLCs significantly reduce wiring, installation, and maintenance costs. Need to upgrade or expand your system? No problem. PLCs allow for easy integration of new I/O modules, communication protocols, or updated logic. PLCs offer built-in diagnostic tools and status indicators that simplify troubleshooting, reduce downtime, and improve system visibility. While there are many benefits of PLC, it's equally important to consider their limitations. Here’s a side-by-side comparison: You might wonder, why switch from relay logic or hard-wired controls to PLCs? The answer lies in their flexibility and efficiency. Traditional Logic Systems are difficult to modify, require extensive wiring, and are not scalable. PLCs, on the other hand, allow for: This is why PLC is preferred over traditional logic system solutions in almost every modern automation setup. Choosing PLCs for your automation needs can lead to long-term operational benefits: Despite their advantages, here are some limitations of PLC you should be aware of: Not Ideal for High-Level Computing: PLCs are built for control, not for data-heavy applications like image processing or AI. Initial Cost: The setup cost can be higher compared to basic relay systems. Programming Skill Required: More complex applications need experienced engineers for efficient logic design. However, these limitations are often outweighed by the flexibility and power PLCs offer. To wrap it up, the advantages of PLC make them the preferred automation solution in industries across the globe. From cost savings and flexibility to real-time performance and ease of use, PLCs provide everything a modern control system needs. While understanding the PLC advantages and disadvantages helps you make an informed choice, one thing is clear—PLCs continue to be the cornerstone of smart automation systems. PLCs offer high reliability, easy programmability, modular design, and real-time control—making them ideal for industrial automation. Some limitations include higher upfront costs, limited computing power in small models, and the need for programming expertise. PLCs reduce wiring complexity, offer flexibility in logic updates, and support centralized control, unlike rigid traditional relay systems. Manufacturing, packaging, automotive, food processing, oil and gas, and energy sectors benefit heavily from PLC automation.Key Advantages of PLC in Industrial Automation

2. Easy to Program and Modify

3. Real-Time Operation

4. Compact and Modular

5. Cost-Effective

6. Flexible and Scalable

7. Advanced Diagnostics and Troubleshooting

PLC Advantages and Disadvantages: A Balanced View

Advantages of PLC Disadvantages of PLC High reliability and durability Higher initial cost than relay systems Easy to program, modify, and troubleshoot Requires skilled personnel for complex systems Modular and scalable architecture Limited handling of very large-scale processes Real-time and high-speed operation Memory and processing power constraints in small models Compact and space-efficient May need external modules for advanced tasks Why PLC Is Preferred Over Traditional Logic Systems

Benefits of PLC for Businesses

Increased Productivity: Fast cycle times and consistent operation.

Better Quality Control: Accurate, repeatable logic ensures process consistency.

Future-Readiness: PLCs integrate easily with Industry 4.0 technologies.Limitation of PLC: When Is It Not Ideal?

Conclusion: Why PLCs Are the Smart Choice

FAQs About PLCs

Q1. What are the primary advantages of PLC?

Q2. What are the disadvantages of PLC?

Q3. Why is PLC better than traditional logic systems?

Q4. What industries benefit most from PLCs?

Related Blogs