PLC Working Principle: How a PLC Works in Industrial Automation

In today’s world of automation, Programmable Logic Controllers (PLCs) are the unsung heroes operating behind the scenes. Whether you’re managing a manufacturing line, an assembly process, or a smart building, understanding the PLC working principle is key to optimizing performance and reducing downtime. In this blog, we’ll give you a clear intro to PLC, explain how a PLC works, and walk you through the operation of a PLC step-by-step—without any unnecessary technical jargon. At the heart of every automation system lies a simple question: How does the PLC work? The answer lies in its basic principle—scan, process, and output. Let’s take a practical example to understand how PLC works: Imagine a conveyor belt system in a factory: This entire process is controlled through the operation of a PLC, which monitors the sensor input, executes the logic, and controls the motor. The operation of a PLC involves a few critical hardware components working together: The brain of the PLC. It processes the input signals, executes the control program, and generates output responses. It provides the necessary voltage and current for the PLC to function. These allow the PLC to interface with the real world by connecting to field devices like sensors and actuators. A PC or handheld terminal is used to upload or modify the control logic in the PLC.PLC Working Principle Explained

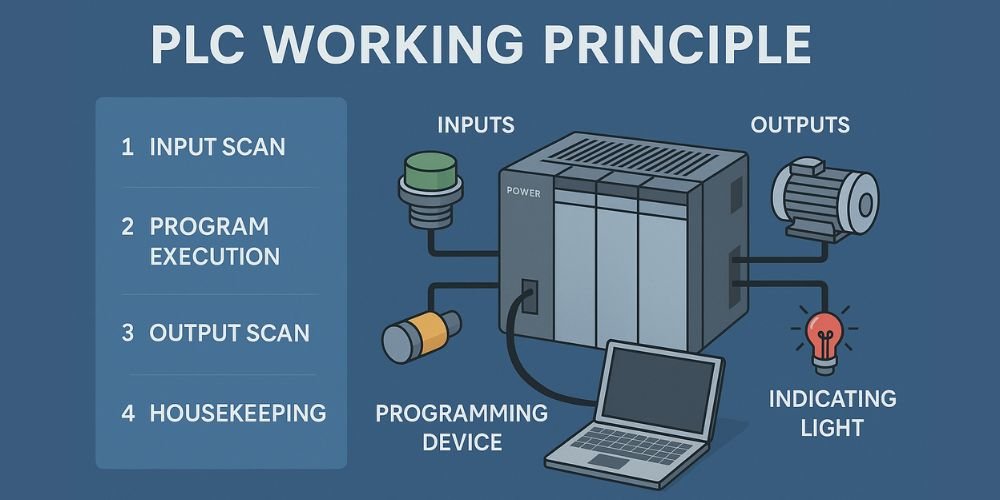

✔️ The PLC Working Principle Follows These 4 Steps:

Input Scan: The PLC begins its cycle by scanning all the connected input devices—sensors, switches, limiters, etc.—to detect their current status (ON or OFF).

Program Execution: After the input scan, the PLC executes the logic written by the programmer. It uses the data from the inputs to determine what the output should be.

Output Scan: Based on the logic results, the PLC updates the output devices—relays, motors, lights, alarms, etc.

Housekeeping: The final step involves internal tasks like communication with other devices, error checking, and diagnostics before starting the next scan cycle.

This cycle happens in milliseconds, allowing real-time automation with incredible precision.How PLC Works in Real-World Applications

Operation of a PLC: Components Involved

1. Central Processing Unit (CPU)

2. Power Supply

3. Input/Output Modules

4. Programming Device

Key Features That Make PLCs Ideal for Industrial Use

Real-Time Processing: PLCs make decisions in real time based on current inputs.

Rugged Design: Built to operate in harsh environments with vibration, dust, and electrical noise.

Modular Configuration: You can expand I/O modules as needed.

Flexible Programming: Easily modify control logic without changing the entire setup.

- Benefits of Understanding the PLC Working Principle

Whether you're an engineer, technician, or student, learning the PLC working principle offers several advantages:

- Better fault diagnosis and troubleshooting

- Improved system optimization

- Effective programming and logic design

- Cost-saving through efficient automation

Summary: Understanding How PLC Works

To summarize, a PLC operates by continuously scanning inputs, executing a user-defined logic program, and updating outputs. This scan cycle is the essence of how a PLC controls real-world devices efficiently and reliably.

Knowing how a PLC works, along with its components and functionality, is crucial for anyone involved in automation or control engineering. Whether you're just getting started or are a seasoned professional, mastering the operation of a PLC can significantly enhance your automation skills.

Frequently Asked Questions

Q1. What is the basic working principle of a PLC?

The PLC follows a continuous cycle of scanning inputs, executing logic, and updating outputs in real time.

Q2. How does a PLC read and respond to data?

PLCs read input signals from field devices, process them based on programmed logic, and then control output devices accordingly.

Q3. Why is understanding the operation of a PLC important?

It helps in designing better automation systems, troubleshooting problems quickly, and maximizing efficiency.