Top 17 Applications of HMI

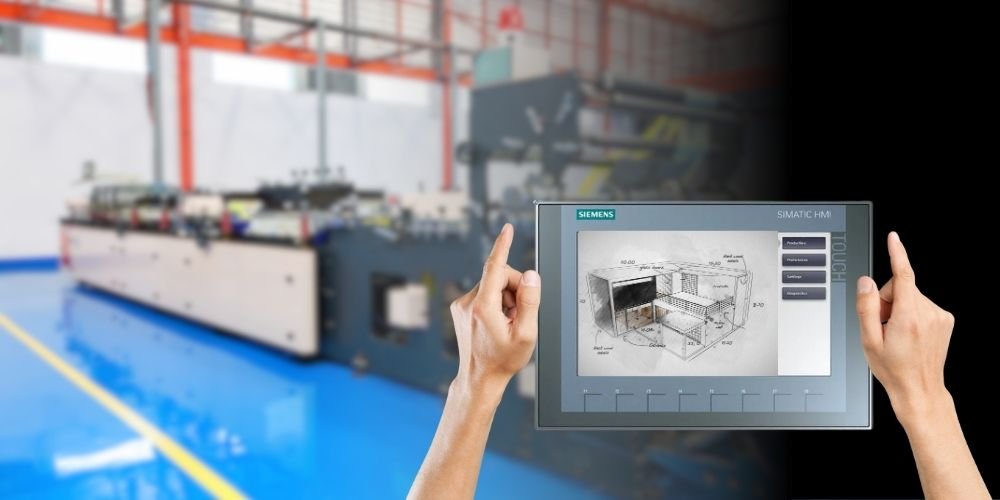

Human Machine Interface (HMI) screens play a crucial role in how operators interact with machines. Whether it’s a factory floor, power station, or water treatment plant, HMI technology helps make industrial processes smarter, safer, and more efficient. Here’s a quick look at the real-world applications of HMI screens across different industries. In production environments, HMI screens are used to: They’re often installed on control panels, packaging machines, and robotic arms to offer centralized control and visibility. In energy systems like solar farms, wind turbines, or thermal power plants, HMIs: HMI screens help technicians respond faster to faults and optimize system efficiency. HMI applications in this sector include: With an HMI, operators can manage complex systems from a single screen—often remotely. In food processing and packaging plants, HMI screens: HMIs also help with traceability and compliance in highly regulated environments. In pharma, precision and documentation are critical. HMIs assist with: GMP-compliant HMIs support both production and validation workflows. In packaging lines, HMI screens allow users to: Changeovers become quicker and more accurate with touchscreen interfaces. HMI screens are also used in smart buildings for: This gives facility managers a centralized interface for real-time monitoring and remote adjustments. HMI screens are integrated into: They offer operators a clear visual of status, alerts, and automation functions on the go. HMI screens are used extensively in: In automotive plants, they simplify complex processes and reduce errors during assembly and quality checks. In oil rigs and refineries, HMI screens are used for: They provide safe and centralized control in high-risk environments. In this high-tech field, HMI screens: Precision, speed, and reliability make HMIs a core part of mission-critical operations. HMIs in textile plants help with: They enhance consistency in fabric quality and minimize downtime. Heavy-duty HMI screens are used to: Dustproof, shock-resistant HMIs ensure reliable performance in harsh mining environments. In solar, wind, and hydro systems, HMIs help: Operators can remotely manage decentralized energy sources through cloud-connected HMI platforms. HMI screens are now seen in: They make modern agriculture more precise and data-driven. In high-speed presses and die-cutters, HMIs: This reduces setup time and waste, improving production consistency. In cleanroom fabs, HMIs are used for: They must be ultra-reliable and compatible with cleanroom standards. HMI screens are more than just fancy displays—they are the control hub of modern industrial and infrastructure systems. From shop floor to power plant, they improve visibility, boost safety, reduce errors, and drive efficiency. As industries evolve, the applications of HMI will only expand further with the rise of IIoT, edge computing, and remote operations. Related Blogs1. Manufacturing & Automation

2. Energy & Power Plants

3. Water & Wastewater Treatment

4. Food & Beverage Industry

5. Pharmaceutical Manufacturing

6. Packaging and Labeling Machines

7. Building Automation Systems

8. Transportation and Logistics

9. Automotive Industry

10. Oil & Gas

11. Aerospace & Defense

12. Textile Industry

13. Mining and Metals

14. Renewable Energy Systems

15. Agriculture & Smart Farming

16. Printing & Packaging Presses

17. Semiconductor Manufacturing

Final Thoughts