How HMI Works: The Brain Behind Industrial Interaction

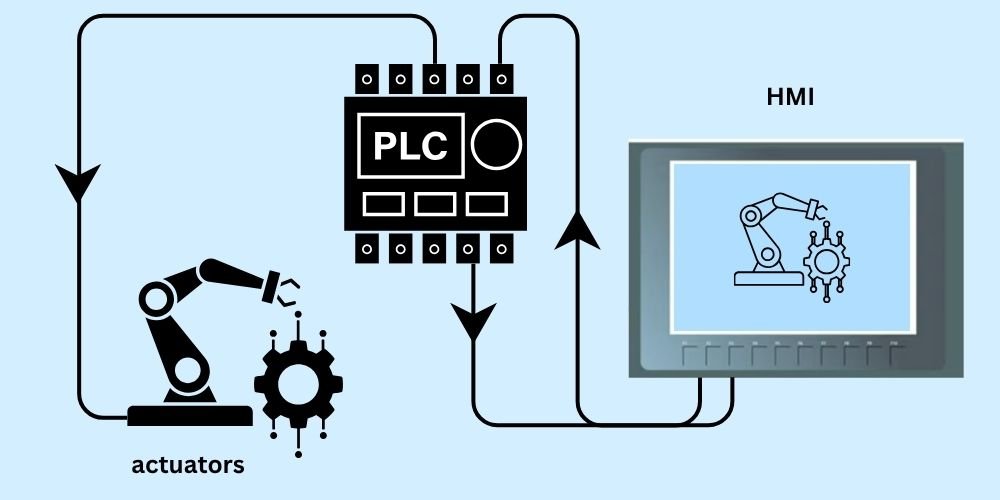

A Human Machine Interface (HMI) screen works as the central point of interaction between operators and industrial machines. But what’s happening behind that responsive touchscreen? Let’s break it down. At its core, an HMI screen works by receiving data from a controller (usually a PLC or PAC), processing that data, and visually displaying it to the operator in real time. The operator can then respond by touching the screen or using buttons to send commands back to the machine. It’s a two-way communication system: The HMI gets real-time input from: Communication happens via protocols like Modbus, Ethernet/IP, or Profibus. The data is then processed by the HMI’s internal software. It interprets sensor values or machine states and converts them into: Operators see this live data on the HMI screen in a graphical format, making complex processes easier to understand. Touching a button or icon on the HMI sends a command back to the PLC or machine, such as: The HMI acts as the middleman, instantly converting user actions into machine-readable commands. Once the machine receives a command, it updates its internal state. This change is sent back to the HMI, which updates the screen—creating a closed feedback loop for real-time control and monitoring. This entire process happens in milliseconds. HMI screens work by bridging the gap between people and machines, enabling safe, efficient, and real-time control of industrial systems. Their power lies not in the hardware alone, but in their ability to process, display, and act on live data in a way that humans can easily understand. Related BlogsHow HMI Works: The Brain Behind Industrial Interaction

The Core Concept of How HMI Works

Machine → HMI → Human → HMI → MachineStep-by-Step: How HMI Works in Real-Time

1. Data Collection from PLCs or Sensors

2. Processing and Visualization

3. User Input and Control

4. Feedback Loop

Simplified Example: Packaging Line HMI

Final Thoughts