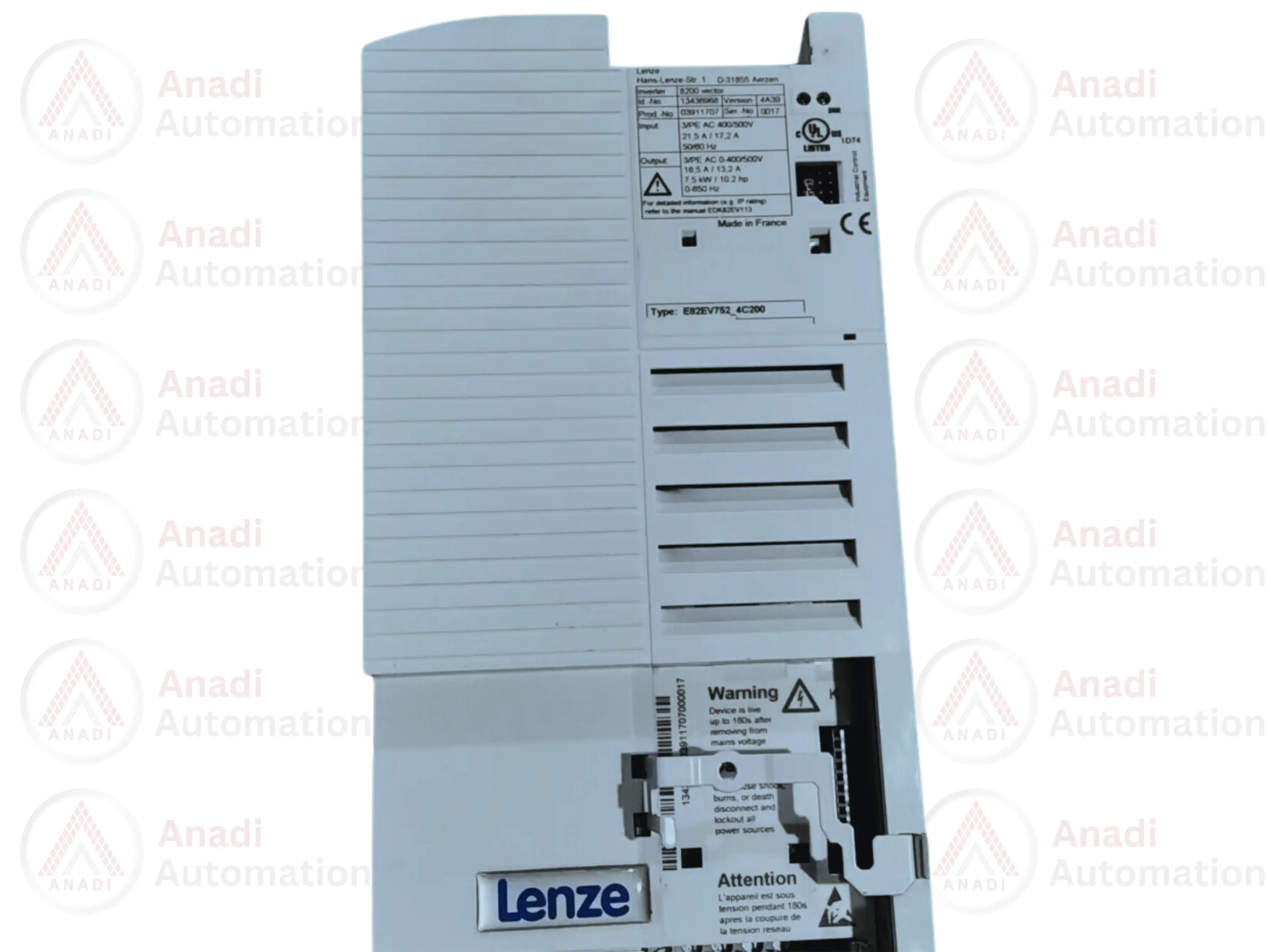

Technical specifications for E82EV552_4C200

Lenze E82EV552_4C200 – Precision Motor Control with Advanced Vector Drive Technology

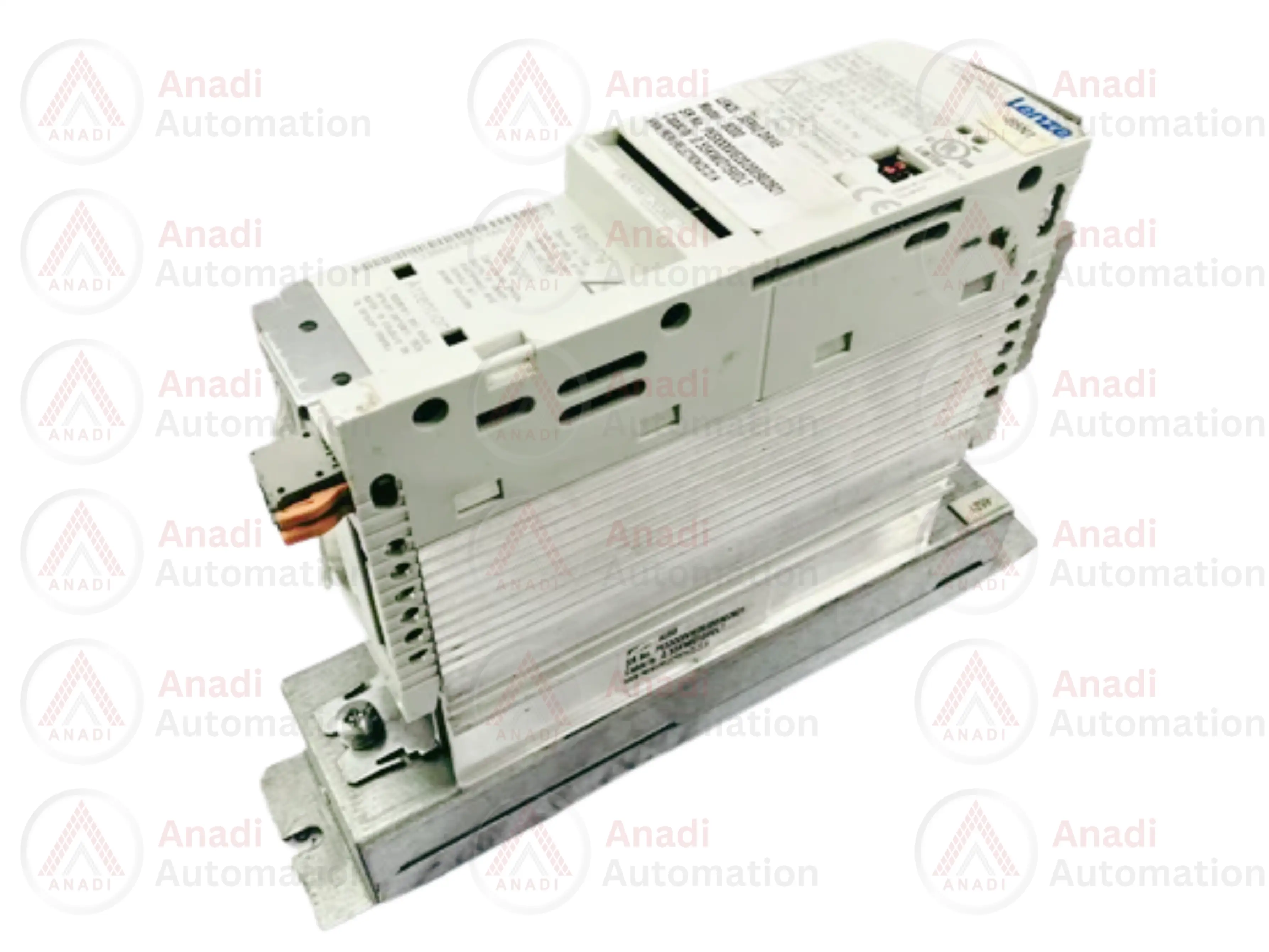

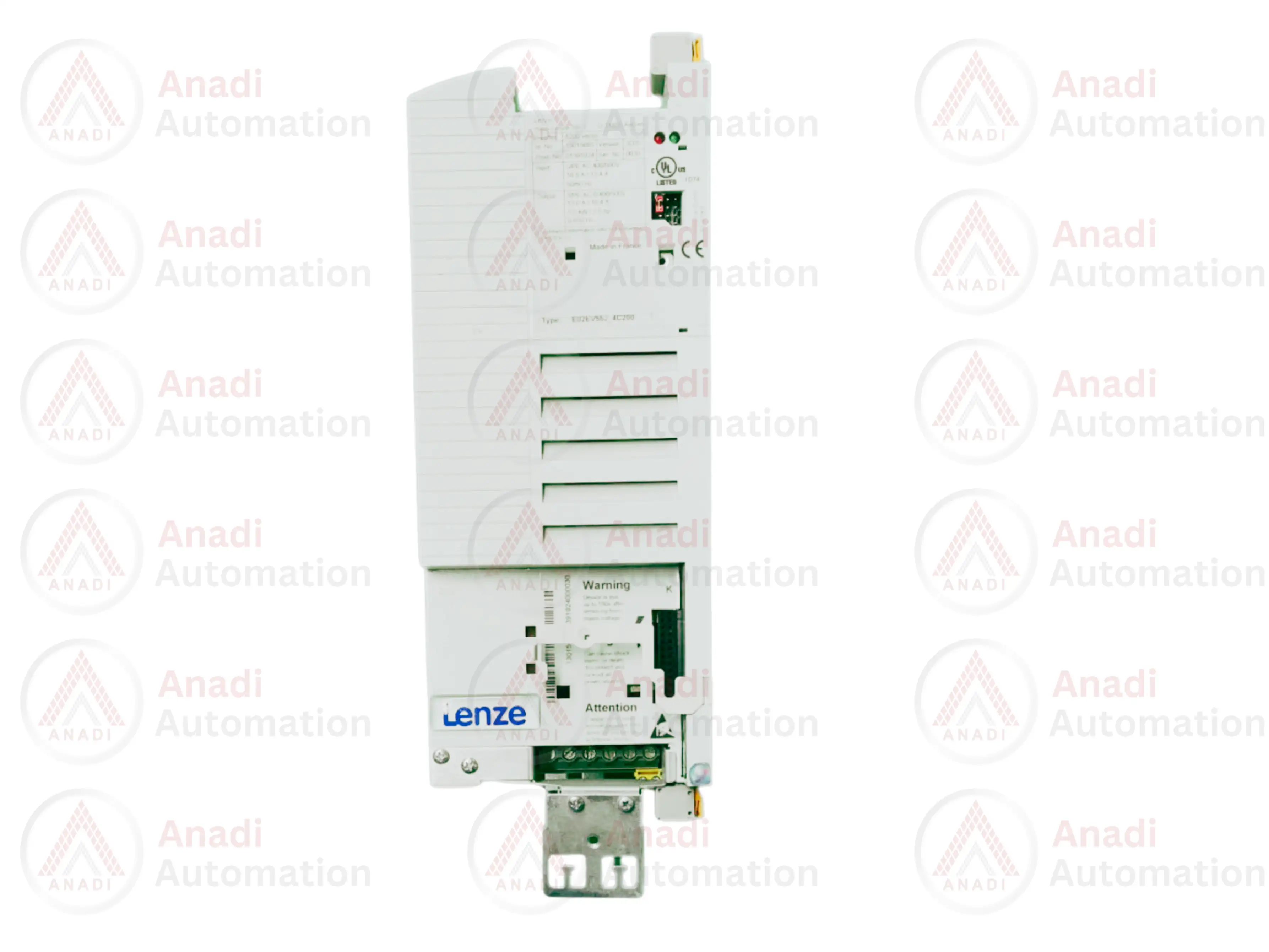

The Lenze E82EV552_4C200 is a robust and intelligent frequency inverter from the 8200 Vector series, purpose-built to deliver advanced motor control capabilities in industrial automation environments. With support for both vector control and voltage/frequency (V/f) control, this drive enables precise regulation of speed and torque, ensuring optimum performance across a broad range of motor-driven applications.

Designed for three-phase 400/500V AC input systems, the E82EV552_4C200 can generate a 0–460V AC output and provides 5.5 kW (7.5 HP) of rated power. With a broad frequency range of 0–650 Hz, this inverter offers excellent flexibility to accommodate dynamic motor speed adjustments, especially in demanding environments such as conveyors, compressors, packaging systems, and processing equipment.

At the core of the E82EV552_4C200’s performance is its dual-mode control strategy: vector control for high-performance applications requiring rapid response and torque accuracy, and V/f control for more traditional constant torque loads. This adaptability allows engineers to fine-tune motor behavior according to the exact needs of the application.

The inverter includes integrated communication interfaces such as RS232 and CANopen, supporting seamless communication with industrial controllers. Additionally, it supports optional fieldbus modules (including PROFIBUS and DeviceNet), providing the flexibility to integrate with a wide range of industrial networks and automation systems.

Designed for control cabinet installation, the unit conforms to IP20 protection class standards. Its panel-mount design makes it easy to incorporate into existing electrical setups, while the cooling method can be adapted between natural convection and forced ventilation, depending on enclosure design and operating temperature.

With a compact and reliable build, the E82EV552_4C200 is ideal for applications where space efficiency and operational durability are priorities. Weighing just 2.72 kg, the inverter offers a favorable power-to-weight ratio, making installation and maintenance straightforward.

This model also emphasizes system safety and durability. Built in Germany, it reflects Lenze’s commitment to high manufacturing standards and long-term reliability in industrial environments. The 8200 series also allows for easy scalability with consistent programming tools and accessories, making system upgrades smooth and efficient.

In conclusion, the Lenze E82EV552_4C200 frequency inverter is a versatile, high-performance drive engineered for industrial environments that demand accuracy, responsiveness, and integration flexibility. Whether for retrofits or new installations, it provides excellent control and communication capabilities for a wide range of motor control tasks.

.webp)

Call Us

Call Us

WhatsApp

WhatsApp

Get Quote

Get Quote

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.webp)