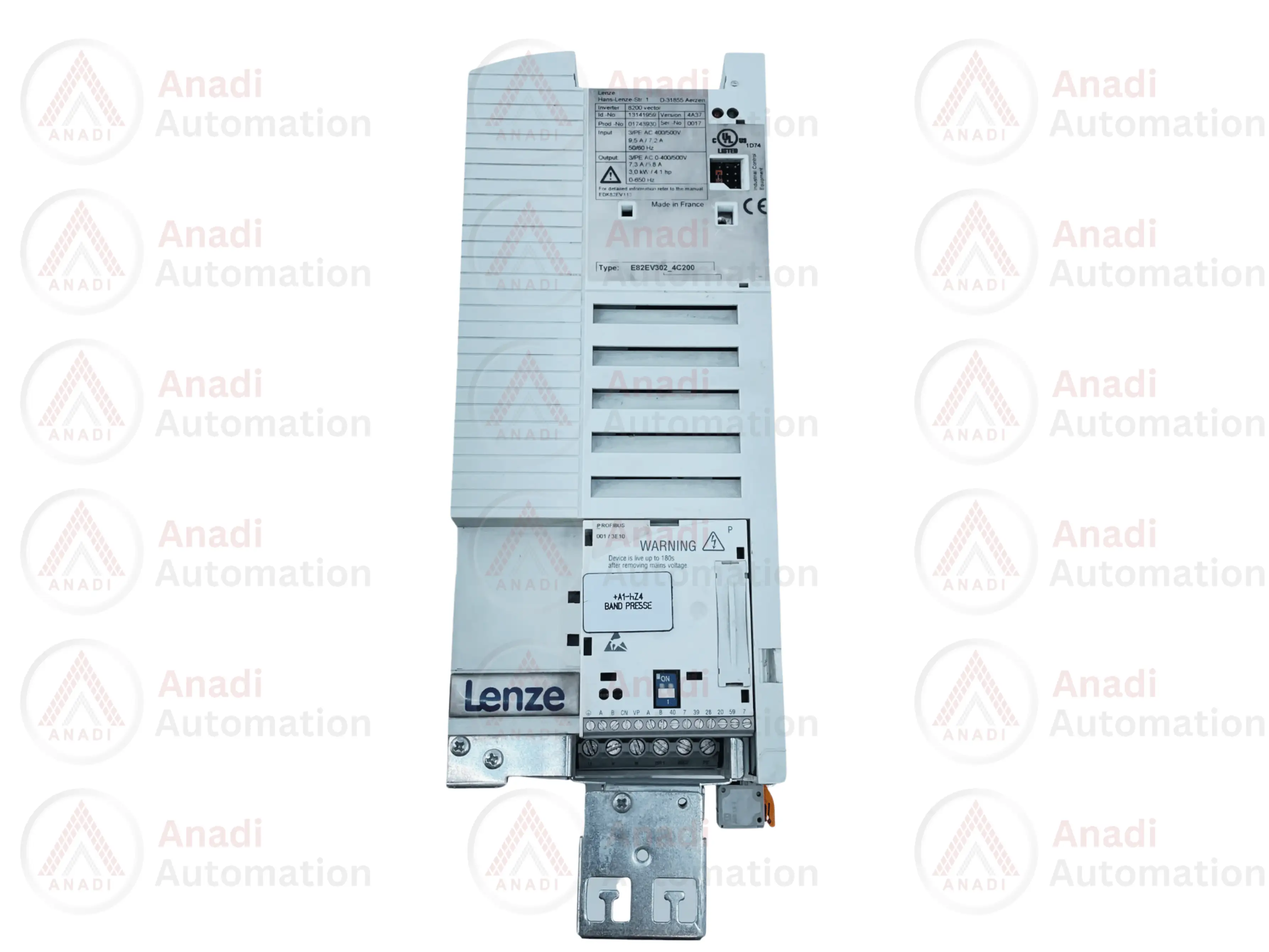

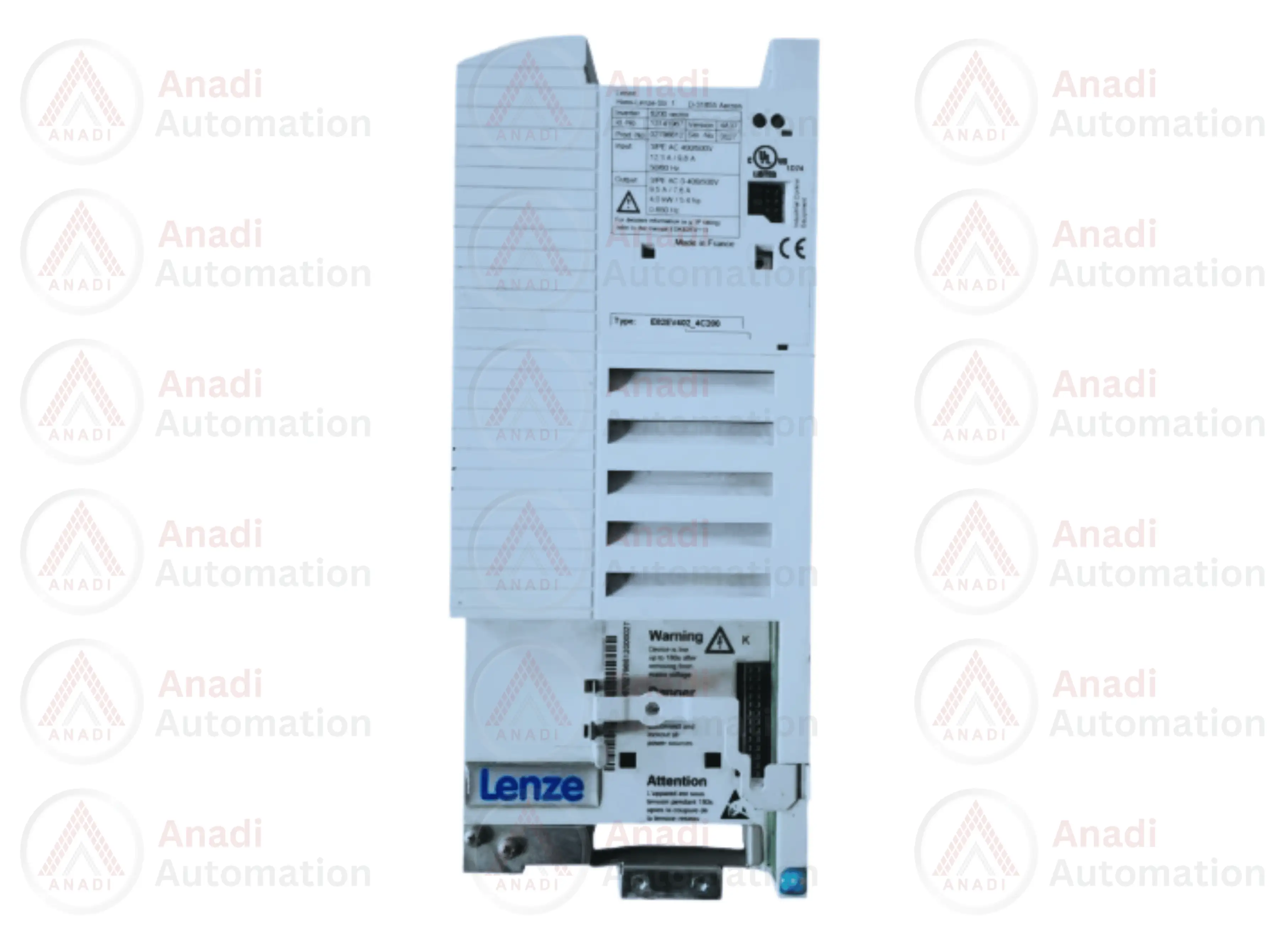

Technical specifications for E82EV402_4C200

Lenze E82EV402_4C200 Frequency Inverter – Advanced Vector Control for Precise Industrial Motor Operation

The Lenze E82EV402_4C200 is a robust and versatile frequency inverter from the renowned 8200 Vector series, designed specifically for precision motor speed and torque control in demanding industrial environments. This inverter combines cutting-edge vector control technology with reliable engineering, offering seamless integration into a variety of automation and drive systems.

With a power rating of 4 kW (5.4 HP), the E82EV402_4C200 is optimized for use with three-phase motors, supporting input voltages of 400V or 500V AC to accommodate different power supply standards worldwide. The inverter’s output voltage matches the input (0-400/500V AC), ensuring compatibility with a broad range of motor types and applications. It delivers an output frequency range of up to 650 Hz, providing excellent flexibility to control motor speed across a wide spectrum, from low-speed precision tasks to high-speed operations.

The inverter supports both vector control and voltage/frequency (V/f) control modes, allowing it to deliver smooth and accurate motor speed regulation tailored to the needs of specific industrial processes. Vector control enhances dynamic response and torque precision, making it ideal for applications such as conveyors, pumps, mixers, and packaging machinery where motor performance directly impacts productivity and product quality.

Engineered with a compact, panel-mounted design weighing just 2.73 kg, the unit is well-suited for installation inside control cabinets where space-saving is essential. Its IP20-rated enclosure protects against solid objects and provides safe operation within controlled industrial environments. Cooling is managed through natural convection or forced cooling, depending on the installation setup, ensuring efficient heat dissipation and long operational life.

In terms of compliance, this frequency inverter holds multiple certifications, including CE, UL, and cUL, which affirm its conformity with rigorous international safety and performance standards. This makes the E82EV402_4C200 a dependable choice for global deployment in automation systems.

The model’s design variant “200” indicates it does not include an EMC filter, making it suitable for installations where electromagnetic compatibility is managed separately. This design flexibility allows users to tailor system configurations according to their specific requirements.

Overall, the Lenze E82EV402_4C200 Frequency Inverter stands out as an efficient, high-performance motor control solution. Its advanced vector control capabilities, wide frequency range, and solid industrial design make it a valuable component in modern automation setups, contributing to enhanced process control, energy savings, and system reliability.

.webp)

Call Us

Call Us

WhatsApp

WhatsApp

Get Quote

Get Quote

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.webp)