- We Care, Production Should Not Stop.

- Home

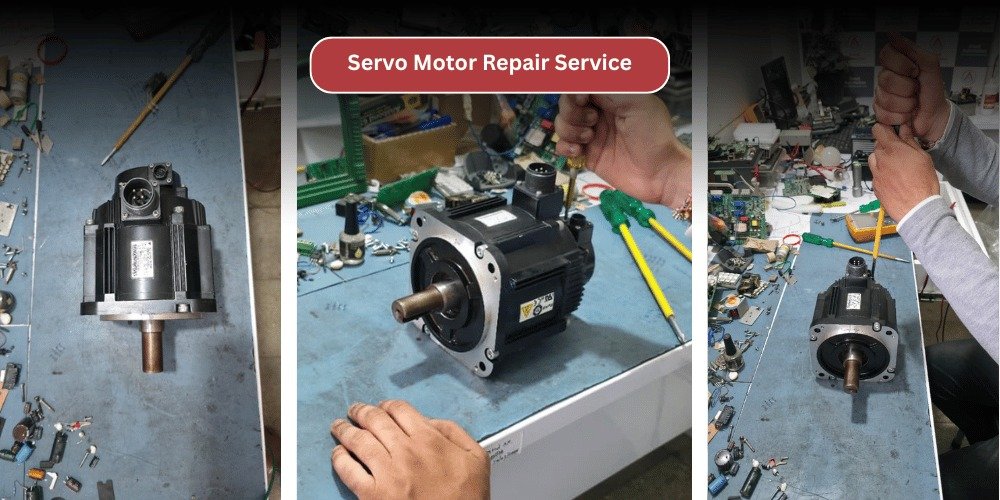

- Servo Motor Repair Service

Precision Servo Motor Repair Services – Fast, Reliable & Affordable

When your servo motor fails, it doesn’t just stop the machine—it can halt your entire operation. That’s where we come in. We provide expert servo motor repair services to get your equipment back online quickly and affordably. Whether it’s a minor encoder issue or a complete motor failure, our trained technicians can restore your servo motor to like-new condition—helping you avoid costly replacements and downtime.

Our Successful Servo Motor Repair Work

Servo Motor Repair

Note:All repairs are handled by Anadi Automation with a warranty provided by us. This warranty does not come from Manufacturer, and we are not affiliated with any brands in providing this warranty

Why Choose Us for Servo Motor Repairs?

-

🔧 All Major Brands Supported

We repair a wide range of AC and DC servo motors from leading manufacturers like Siemens, Yaskawa, Mitsubishi, Allen-Bradley, Fanuc, Schneider, and more.

Note: We are an independent repair service provider and not affiliated with these brands. -

🧠 In-Depth Technical Knowledge

Our team has years of experience and the diagnostic tools to identify and repair even the most complex motor problems.

-

⚙️ Complete Overhaul Services

We don’t just fix the symptoms—we completely disassemble, clean, inspect, repair, and test every motor to ensure peak performance.

-

🔍 Encoder & Resolver Expertise

We specialize in repairing and re-aligning feedback devices like encoders, resolvers, and tachometers for accurate positioning and speed control.

-

🧪 Dynamic Load Testing

All motors are tested under real-world load conditions to ensure reliability and optimal functionality.

-

💰 Cost-Effective Solution

Repairing your servo motor is often far more affordable than buying new. We help you get the most out of your existing equipment.

-

🛡️ Warranty Protection

All repairs come with a warranty by Anadi Automation, so you can trust in the quality of our work.

(The warranty is provided solely by Anadi Automation and not by the original manufacturer.)

What We Repair

We service a wide variety of servo motor issues, including:

- Burnt windings or short circuits

- Worn-out bearings or broken shafts

- Faulty encoders, resolvers, or tachometers

- Contamination from oil, dust, or moisture

- Overheating or insulation breakdown

- Damaged connectors, brakes, or housings

- Excessive vibration or noise

- Out-of-spec motor performance

- Burnt or damaged circuit boards

We handle motors used in CNC machines, robotics, printing equipment, packaging lines, and other industrial applications.