When setting up an automation system, understanding the servo motor connection is critical. Proper wiring ensures the motor runs smoothly, communicates with the controller, and responds accurately to commands.

Whether you're installing a servo in a CNC machine or a robotic arm, the basics of servo motor connection remain the same.

Key Components in a Servo Motor Connection

- Servo Motor – The motor that performs the motion

- Servo Drive / Amplifier – Supplies power to the motor and receives commands from the controller

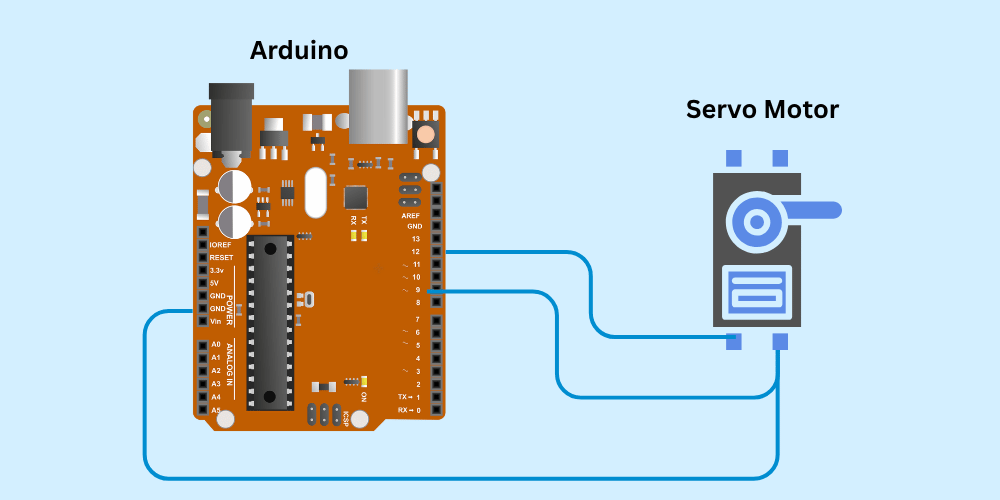

- Controller / PLC / Motion Controller – Sends movement commands

- Feedback Device (Encoder) – Monitors position, speed, and direction

- Power Supply – Feeds voltage and current to the system

Common Servo Motor Connections

1. Power Connection

- The servo motor connects to the servo drive's power terminals

- Typically includes U, V, W phases for 3-phase motors

- In small DC servos, it may just be V+ and GND

2. Encoder Feedback Connection

- The encoder connects back to the drive or controller

- Transmits real-time feedback via differential signals (A, B, Z channels)

3. Control Signal Connection

- Servo drive connects to the controller (PLC or CNC system)

- Uses analog, pulse train (step/dir), or communication protocols like:

- EtherCAT

- CANopen

- Modbus

- Profinet

- RS-485

4. Brake Connection (if applicable)

- Some servos have an electromagnetic brake

- Wired to a separate control output for holding position when powered off

Safety Tips for Connecting Servo Motors

- Always power off before wiring

- Check voltage ratings and pinouts from the datasheet

- Use shielded cables for encoder and signal lines to avoid noise

- Ensure proper grounding to prevent erratic motion or damage

- Double-check motor-phasing (UVW) for correct rotation direction

Final Thoughts

Making the right servo motor connection ensures accurate control, reliable motion, and a long-lasting system. A well-connected servo setup creates a seamless communication loop between the controller, drive, motor, and feedback device.